Craftsmanship – how wedding rings are made at Fischer

In our series on craftsmanship at INHORGENTA, we take a look at where tradition, craftsmanship, technology, and genuine jewelry culture converge. Nowhere is this more evident than in wedding rings – those small but meaningful symbols meant to last a lifetime.

In Pforzheim, the historical center of German jewelry manufacturing, Fischer Trauringe is one of the manufacturers that impressively demonstrate how classic goldsmithing, in-house material developments and responsible production work together today.

Highest quality, craftsmanship, Made in Germany

As one of the few manufacturers, Fischer produces all its wedding rings entirely at its Pforzheim location – from alloying and rolling to turning, final surface finishing, and engraving. This complete in-house production guarantees not only maximum control over every step of the process but also the craftsmanship for which German goldsmithing is internationally renowned. For the bridal couple, as well as for retailers, this means: high quality, short supply chains, fast response times, and a reliable partner with genuine vertical integration.

Innovative materials & designs:

Fischer is known for its innovative materials technology and regularly develops its own color alloys, opening up exclusive design possibilities. Of particular note is FischerCarbon®, a combination of precious metal and carbon that unites modern aesthetics with high dimensional stability. This clearly positions the brand as a technologically leading manufacturer that masters both tradition and innovation.

The topic of diamonds

The natural diamonds used by Fischer come exclusively from partners who are certified according to the standards of the Responsible Jewellery Council (RJC).

Fischer works exclusively with diamond suppliers who demonstrably meet the requirements of the RJC – the most important international standard for responsible supply chains in the jewelry and watch industry. This ensures that all diamonds used come from ethically sound sources and that the entire supply chain is conducted in a socially, environmentally, and economically responsible manner.

Sustainability – even in wedding rings

Sustainability is an integral part of the company's philosophy. Fischer processes exclusively recycled precious metals, the purity of which is ensured through state-of-the-art testing methods. Furthermore, the company covers the majority of its energy needs itself by utilizing a large-scale photovoltaic system, thereby actively reducing its ecological footprint. This is complemented by efficient filter and recycling systems that conserve resources and minimize emissions.

The "FS" hallmark serves as proof of authenticity and quality.

Each wedding ring bears the brand's signature "FS" hallmark and the gold purity stamp on the inside. This marking guarantees both retailers and end customers a clear connection to the Fischer manufactory and serves as visible proof of origin. It stands for tested quality and a product that meets the company's high standards.

Personalization is a major theme in jewelry, and of course especially in wedding rings.

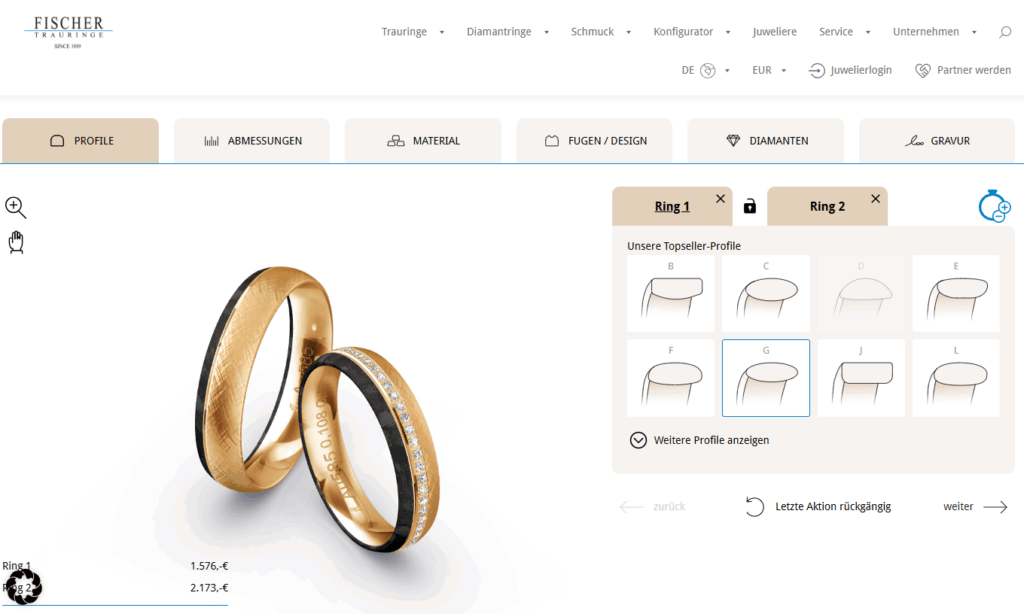

But how does it work? From configurator to "I do" – How a wedding ring is created.

How does a custom-designed wedding ring actually get from the initial sketch to the hand of the bride and groom? The answer lies in a combination of digital design, expert advice, and traditional craftsmanship. It's a process that utilizes technological possibilities without losing the character of a handmade piece of jewelry.

It all starts with an idea – and often with a digital tool:

The configurator. At Fischer, for example, the "Confischerator" allows couples to design their rings directly on the screen according to their own preferences. Whether at the jeweler's or at home: shape, alloy, surface finish, stone setting, or engraving can be tested in real time. Price, material effect, and proportions remain transparent at all times.

This digital preparation provides clarity, but it doesn't replace the expertise of a specialist retailer – it complements it. In a consultation with the jeweler, variations are compared, proportions are coordinated, and questions are answered: Should the ring be crafted in warm apricot gold or classic platinum? Does a hand-finished satin look, a crystal surface, or a polished classic suit the style better? How comfortable should the ring be, how wide should it be – and how can a potential stacking ring be harmoniously integrated? The stone setting also plays an important role: from a subtle diamond to colored accents or lab-grown alternatives, depending on the couple's wishes and preferences.

Once the decision has been made, the actual manufacturing process begins.

Alloys and the production of blanks

The metal is the starting point for every wedding ring. First, the desired alloys are melted – from classic yellow, white, or rose gold to specially developed shades like apricot or caramel gold. Platinum, palladium, or modern material combinations such as carbon-metal alloys are also used.

After alloying, the metal is processed into blanks: It is rolled, its thickness and width are defined, and then it is formed into its basic shape. These initial blanks form the foundation for the later ring – precise, homogeneous, and stable.

Shapes and surfaces

The blank is then transformed step by step into an individual ring. The profile – round, flat, domed, or organically soft – is defined and adjusted. This shaping determines both the wearing comfort and the aesthetic character of a wedding ring.

The surface is the area where craftsmanship becomes particularly visible: from finely mattified surfaces to longitudinally or transversely brushed surfaces to three-dimensionally crafted structures, this is where the feel is created that makes a ring unique.

New structures like "Crystal" demonstrate how vibrant and multifaceted modern surface treatment can be.

Example of special surfaces

stones

If a ring is to be set with diamonds, the meticulous work now begins, requiring precision down to a tenth of a millimeter. The settings are prepared, inspected, and finished by setters. Whether flush-set, channel-set, tension-set, or set in a row in the eternity style – each technique demands its own balance of stability and aesthetics.

This is where the intensity of a stone's effect and its secure setting are determined. Natural diamonds come exclusively from controlled sources and are sorted by color, clarity, and size before being set.

The Polieren

Finally, the ring acquires its final character. Polishing refines the surface – giving it a high-gloss, silky-matte, or deliberately textured finish. Only in this step does the interplay of all the previous work become apparent. Naturally, the high-gloss polishing is primarily done on the inside, as this is where the engraving needs to be clearly legible.

Examples of polished and satin-finished surfaces of the rings:

The engraving

The engraving is ultimately the most personal moment of the entire manufacturing process: it can be done using diamond or laser engraving, in handwriting, symbols, or even fingerprints. This message makes the piece of jewelry unique – and unites design, symbolism, and emotion into a cohesive whole.

Thus, the journey from the configurator to the hands of the bridal couple combines modern technology, personal consultation, and meticulous craftsmanship. This process demonstrates that even in an increasingly digital world, craftsmanship remains the decisive factor – because no algorithm can – at least not currently – replace the experience, intuition, and personal touch of the people who transform a ring into what it ultimately is: a symbol of a shared future.

More on the topic of wedding rings This way

More about Fischer wedding rings: https://www.fischer-trauringe.com/