Craftsmanship Uncovered: Jewelry

How colored gemstones, craftsmanship and Idar-Oberstein tradition combine to form a piece of jewelry in Richard Hans Becker's work:

In a time when so much has become fast-paced, the desire for things that last is growing – for pieces created with knowledge, experience, and genuine craftsmanship. Hardly any place embodies this more than Idar-Oberstein, the historical center of German gemstone processing.

This is where the Richard Hans Becker manufactory has its roots. Since the founder had to melt down his own wedding ring in 1973 to secure his first order, the family business has stood for precise craftsmanship and exceptional colored gemstones. Today, the second and third generations continue this tradition.

The focus on colored gemstones, small series, and unique pieces ensures a quality that is visible in every detail – especially since all the skills and comprehensive knowledge allow almost every step of the process to be carried out in-house. This results in the meticulous work that demonstrates what true craftsmanship means.

The steps of jewelry making – and the craftsmanship behind it:

Draft

The design phase is where the first idea for a piece of jewelry is created – often inspired by a gemstone, a shape, or a moment of light.

Cover image: Here, the designer's artistic flair is evident, as he transforms an abstract inspiration into a clear vision.

Design

The design translates this vision into proportions, lines, and wearability.

Design is a balancing act: it combines aesthetics, functionality and practical feasibility.

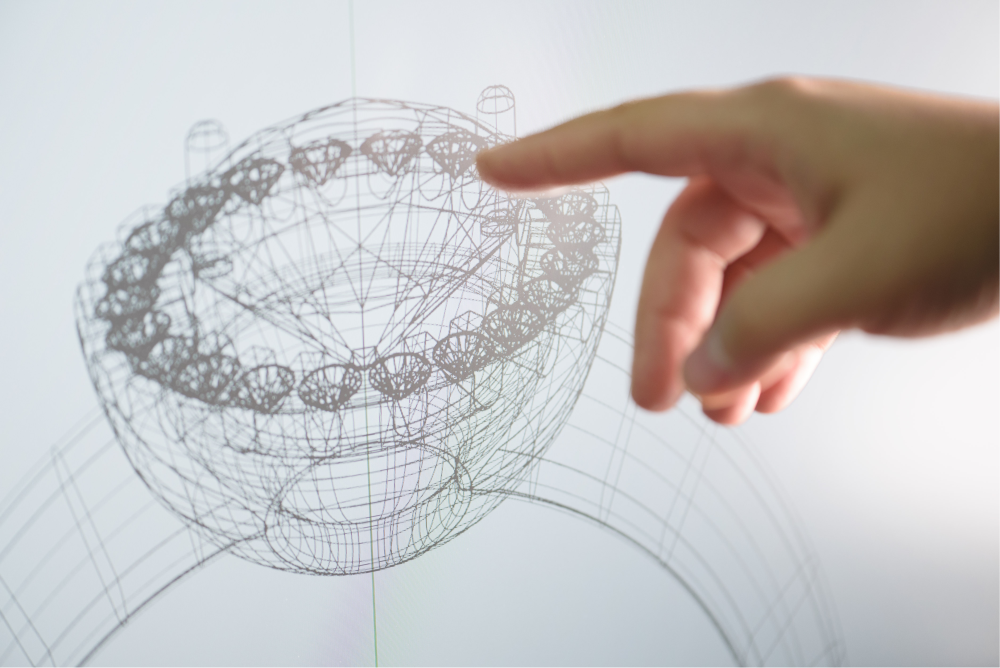

Plotting

During plotting, the design is converted into a technical drawing that precisely defines all dimensions; from this, the first models are created in the 3D printer – previously, this step was carried out by hand and in wax.

These models are ideal for checking dimensions and design, and can even be shown to a customer.

This is the foundation on which goldsmiths work with millimeter precision – precision begins here.

Rollers

Rolling is used to prepare the material, usually gold. During rolling, the precious metal is brought to the desired thickness, making it ideal for further shaping.

A controlled process where strength, experience, and a precisely adjusted tool are crucial.

Glow

The annealing process makes the metal soft and malleable again.

Goldsmiths must master the exact temperature – too hot destroys the structure, too cold has no effect.

Saws

Fine saw blades are used to reveal shapes and to work components of the later piece of jewelry out of the metal.

Sawing requires a steady hand and a feel for material tension – this stage hardly forgives mistakes.

Solder

Soldering is a process used to permanently join individual components together.

Goldsmiths must perfectly coordinate temperature and timing – every soldering point determines stability and appearance.

Clean up

During the finishing process, burrs, unevenness and fine residues are carefully removed.

This is where the foundation for a flawless surface is created – a task that requires patience and precision.

The path of stones

magnifying stones

Each gemstone is examined under a magnifying glass – for purity, i.e., any inclusions, and for the cut to ensure the correct proportions.

A trained eye can immediately tell whether a stone meets the requirements or not.t is suitable for the piece of jewelry for which it is intended.

Sorting stones

During sorting, stones are harmoniously matched according to color, size, and brilliance.

It's an art in itself, because the perfect harmony of the stones determines the final overall effect.

Offcuts

Cut-out is a traditional technique of gemstone setting, in which the setter uses very fine gravers (small engraving tools) to cut material away from the metal so that even small stones can be securely fixed.

Grasp

During the setting process, the gemstones are securely inserted into the prepared settings.

This is considered one of the most delicate steps – one millimeter too much pressure can damage the stone.

polishing

Finally, the piece of jewelry is polished until it achieves its final shine.

Polishers use their experience and sensitivity to bring out the radiance that truly completes a piece of jewelry.

Quality control

Finally, the piece undergoes a complete inspection. This includes everything from the quality and setting of the stones, to the execution of the goldsmithing and surface finish, right down to the ordered size. This ensures that everything meets the highest standards.

It is also noteworthy that all this expertise is not only evident in their own collections, but is also available to jewelers for custom designs and demanding repairs.

This shows that true "craftsmanship" doesn't end with the finished piece of jewelry!

Discover more: https://richard-hans-becker.de/